Teknoseal supplies the TSP range of impregnation sealant. These sealants are used during the vacuum impregnation process to seal the micro porosities in various components.

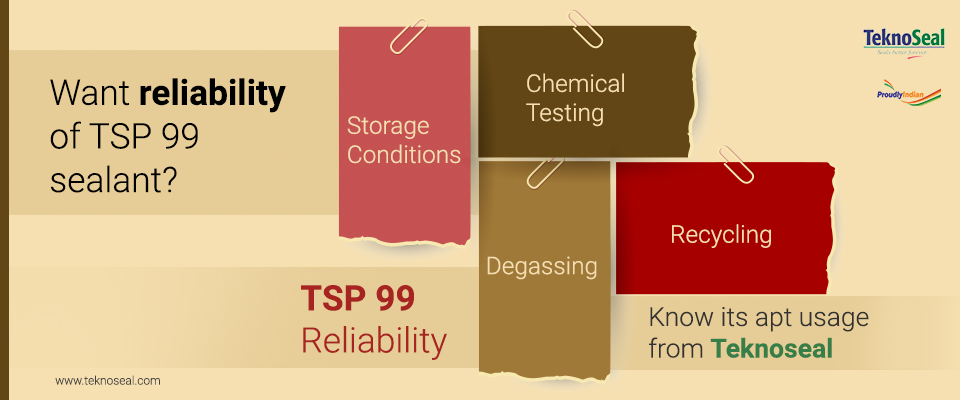

The reliability of the TSP 99 sealant

The TSP 99 sealant range is very reliable because of its following attributes.

It has a working temperature range of -50 degrees Celsius to +220 degrees Celsius. It is completely stable within this range. It has very good washability, and hence there is no need of any after work or cleaning of machined castings, as in the case of complex and intricate machined castings with many tapped and drilled holes. It has very good penetration and adhesion due to which its porosity filling ability is exemplary. Due to its balanced viscosity it can seal both gross and fine porosities. Its stability in conditions of high vacuum enables sealing of extremely fine micro porosities in quick cycle times. Impregnated components are resistant to high pressure and vibrations.

Proper application of special impregnation sealant TSP99 is important to get the good result:

To get good results from impregnation with Teknoseal TSP99 impregnation sealant, it is very crucial to ensure its proper usage. Teknoseal provides technical and Material Safety data sheets and process application manuals which are useful in this regard.

For meticulous usage of this sealant, one must know the precise temperature range in which it must be stored. The effect of ultraviolet radiation and direct sunlight must be avoided. Teknoseal provides recommendations to its customers related to the storage conditions when the impregnation process is in progress and when the impregnation cycle is stopped for a few days. The material of the containers wherein the sealant is stored is also vital.

It is vital to avoid contamination of the sealant bath with oil, solvents and moisture and it is also important to agitate the sealant from time to time by degassing the same. Contamination of the sealant bath leads to imbalance of the viscosity of the sealant and also reduces its effectiveness in sealing performance and penetrability.

For impregnation to be effective, the sealant’s specifications must be within the acceptable limits. So, it is essential to carry out a few laboratory tests on a regular basis to confirm the suitability of the sealant bath for usage. Teknoseal can execute this testing at its technical center and provide detailed reports to customers as desired, to conclude if the sealant is fit for usage or not.